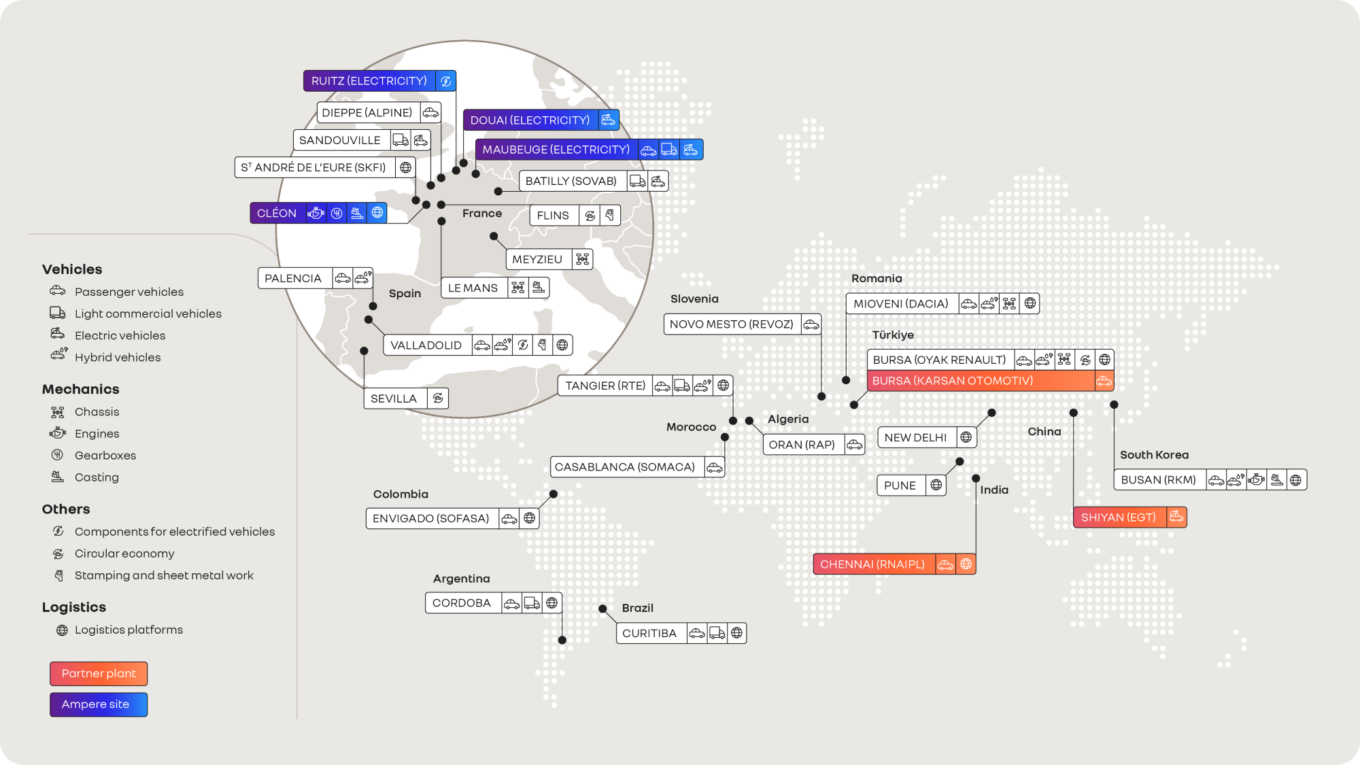

Our plants, design and engineering centres

Facilities on four continents to design and manufacture vehicles and services close to Group markets.

Our locations

The 'Re-Industry' transformation plan aims to turn our historic industrial sites into a more agile, more virtuous and more efficient production base.

01

Sharpening our competitive edge

Building on our optimized manufacturing capacities with the implementation of flexible lines in recent years, our industrial system is becoming faster, more agile, and better able to build new models.

By 2027, we are aiming to shorten vehicle development times from three to two years, and to cut production costs per vehicle by 30% for internal combustion vehicles and 50% for electric vehicles.

02

Digitalising our industrial system

With over 14,000 systems connected worldwide, our industrial metaverse is driving smarter, faster and more efficient production, cutting vehicle delivery times by 60%. Using artificial intelligence, we are able to continuously monitor our energy consumption, adopt a predictive approach and correct any deviations.

03

Accelerating decarbonisation

We are aiming to reduce the energy consumed in production for each vehicle by 40% in France and 30% worldwide between now and 2025, compared with 2021. In terms of emissions from industrial sites, our objective is to achieve net zero carbon by 2030 for sites in Europe, and by 2050 for all industrial sites worldwide.

To achieve this, we are implementing complementary industrial approaches, i.e.: monitoring our sites through our metaverse, reducing workshop size – smaller sites require less heat and light – and opting for renewable energies through partnerships with energy specialists such as Iberdrola in Spain and Comerc Energia in Brazil.

04

Improving quality

We are continuously improving the quality of our cars, in order to achieve excellence. We have made significant progress in this area, with a threefold improvement in vehicle reliability in two years.

05

Developing new skills

To keep pace with changes in the mobility sector and the transformation of our sites, we are training our operational workforce in the pursuit of excellence, teaching them the skills of the future through ReKnow University.

Our corporate university has modules dedicated to transforming skills in our plants.

06

Producing vehicles close to our global markets

Renaulution reaffirms our commitment to France, with new models securing the future of each French plant.

Our production in France will have doubled by 2030 compared with 2019. This robust industrial base is the springboard for our new drive to conquer global markets. Working with leading partners, we are deploying five hubs – in Latin America, Korea, India, Turkey and Morocco – able to meet the needs of the local market while serving as a regional export platform.